1. A Depression, A Dream, and a Deadline

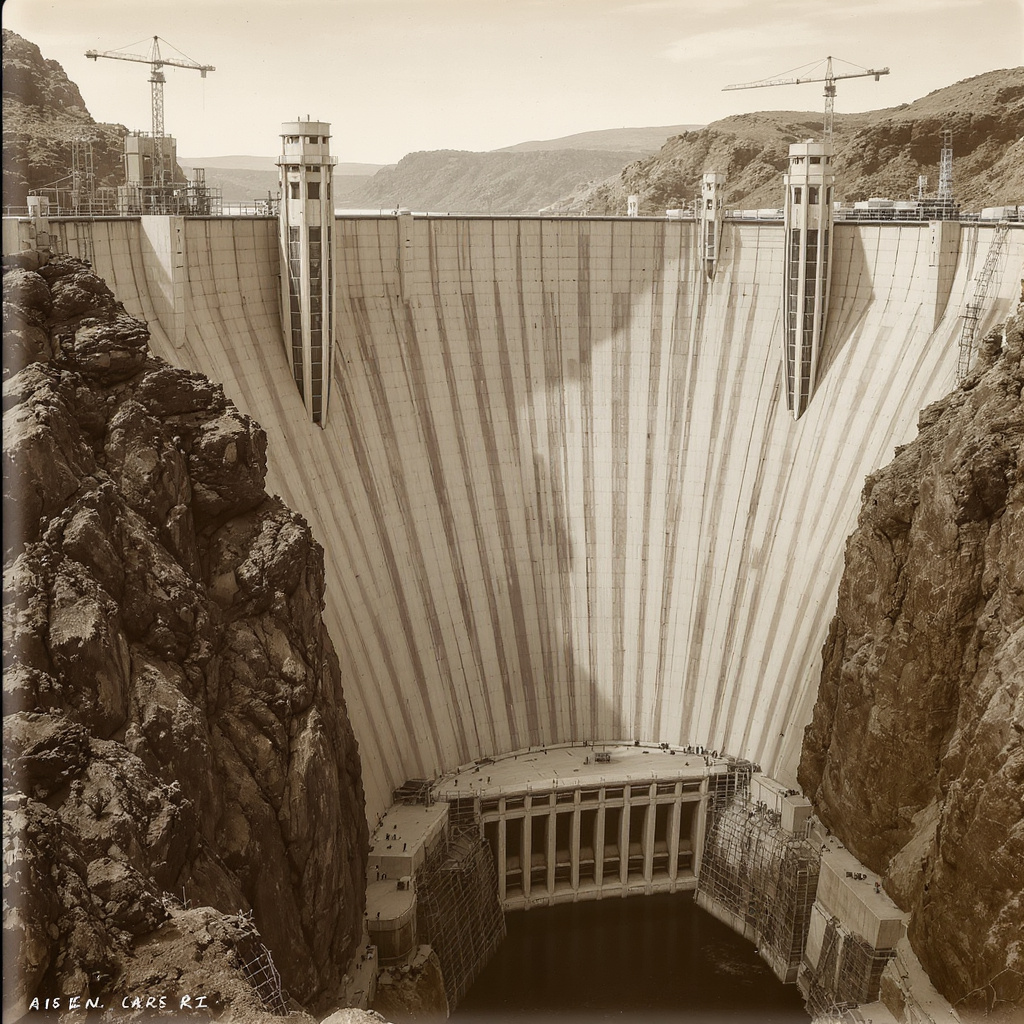

In 1931, the world’s economy had collapsed. Factories stood silent, unemployment soared, and optimism was rare. Yet in this bleak landscape, the U.S. government announced a project so grand it sounded almost absurd — to tame the Colorado River and build a dam so vast it would rewrite history.

The Hoover Dam wasn’t just a structure. It was a statement. It represented economic defiance, political ambition, and engineering bravado. More importantly, it became a case study in cost control under chaos.

Unlike today’s projects where cost overruns are expected, the Dam had none of that luxury. The budget was fixed. Inflation was rising. Labor unrest was real. And yet, it was completed ahead of schedule and under budget.

So how did they do it? Let’s rewind.

2. The Fixed-Price Gamble That Defined Accountability

Before the first shovelful of dirt was moved, the Bureau of Reclamation set the tone — a fixed-price contract.

In today’s world, fixed-price is often feared, especially for complex projects. But in 1931, it was the only way to balance political pressure and financial control.

- The contract was awarded to “Six Companies, Inc.” — a consortium of major construction firms.

- The total value: $48.8 million.

- Any overrun would be absorbed by them, not the government.

This bold model forced innovation.

It compelled managers to plan for uncertainty instead of merely reacting to it.

They built contingency buffers not in spreadsheets, but in clever engineering choices — modular concrete blocks, local sourcing, and mechanical efficiency.

In essence, they transformed risk into routine.

3. The Human Economics of Cost Control

Managing money in a depression was one thing. Managing morale was another.

More than 5,000 workers lived in harsh desert conditions with temperatures soaring above 45°C. Strikes and dissatisfaction could derail the entire operation. The project team understood early that financial discipline required emotional intelligence.

So they did three smart things:

- Predictable Pay, Predictable Peace: Wages were paid on time, in cash, even during economic turmoil. Stability bred loyalty.

- Social Engineering: They built Boulder City — a model town with homes, schools, and markets — ensuring workers felt invested in success.

- Performance Bonuses: Workers who exceeded concrete pouring targets received rewards, turning productivity into pride.

This blend of humanity and economics created what we now call a psychological contract — unwritten, but powerful.

4. The “Concrete Clock” – Where Time Was Money

When the dam’s concrete pouring began in 1933, stopping wasn’t an option. Concrete hardens fast; a pause would mean cracks, waste, and cost disaster.

The solution?

A continuous, round-the-clock operation. Teams worked in shifts, using conveyor belts, cableways, and cooling pipes to pour and cure concrete with surgical precision.

This relentless rhythm was dubbed “The Concrete Clock”.

Every hour mattered. Every cubic yard had a price tag.

Their approach resembled a modern Agile sprint — time-boxed, incremental, and measurable. They didn’t talk in Gantt charts; they lived by them.

5. Lessons Modern Project Managers Often Forget

The Hoover Dam is a century old, yet its financial wisdom feels timeless. Here are five principles that still resonate:

- Define the Risk Appetite Before the Budget.

Don’t allocate funds without defining tolerance. Six Companies, Inc. knew exactly how much risk they could absorb before bidding. - Turn Scarcity into Strategy.

Every constraint is a creative opportunity. They didn’t have endless funds — and that made them smarter. - Make Morale a Line Item.

People under pressure need motivation as much as materials. Every cost sheet should include a morale budget. - Build Clockwork Operations.

When tasks are time-critical, design workflows that can’t afford downtime. The “Concrete Clock” was primitive Agile in motion. - Communicate the Cost Story.

The Hoover Dam wasn’t just well-managed; it was well-narrated. Every senator, engineer, and worker understood why costs mattered.

6. Beyond the Ledger – Cost as a Cultural Code

Project Cost Management is often treated as arithmetic. But in the Hoover Dam, it was philosophy.

They didn’t measure success in spreadsheets; they measured it in shared purpose.

When an entire nation is watching, every dollar becomes symbolic. That symbolism drove accountability.

Today’s PMs can borrow that mindset.

Because cost isn’t just a metric — it’s the mirror of how seriously a project treats its mission.

7. Epilogue – The Legacy of Financial Discipline

Nearly a century later, the Hoover Dam still stands — generating power, supporting millions, and inspiring awe.

It’s a monument not just to engineering, but to the art of doing more with less.

When the world collapses, a good budget can build it back again.

Leave a Reply

You must be logged in to post a comment.