1. Agile’s Industrial Roots – A Hidden Story

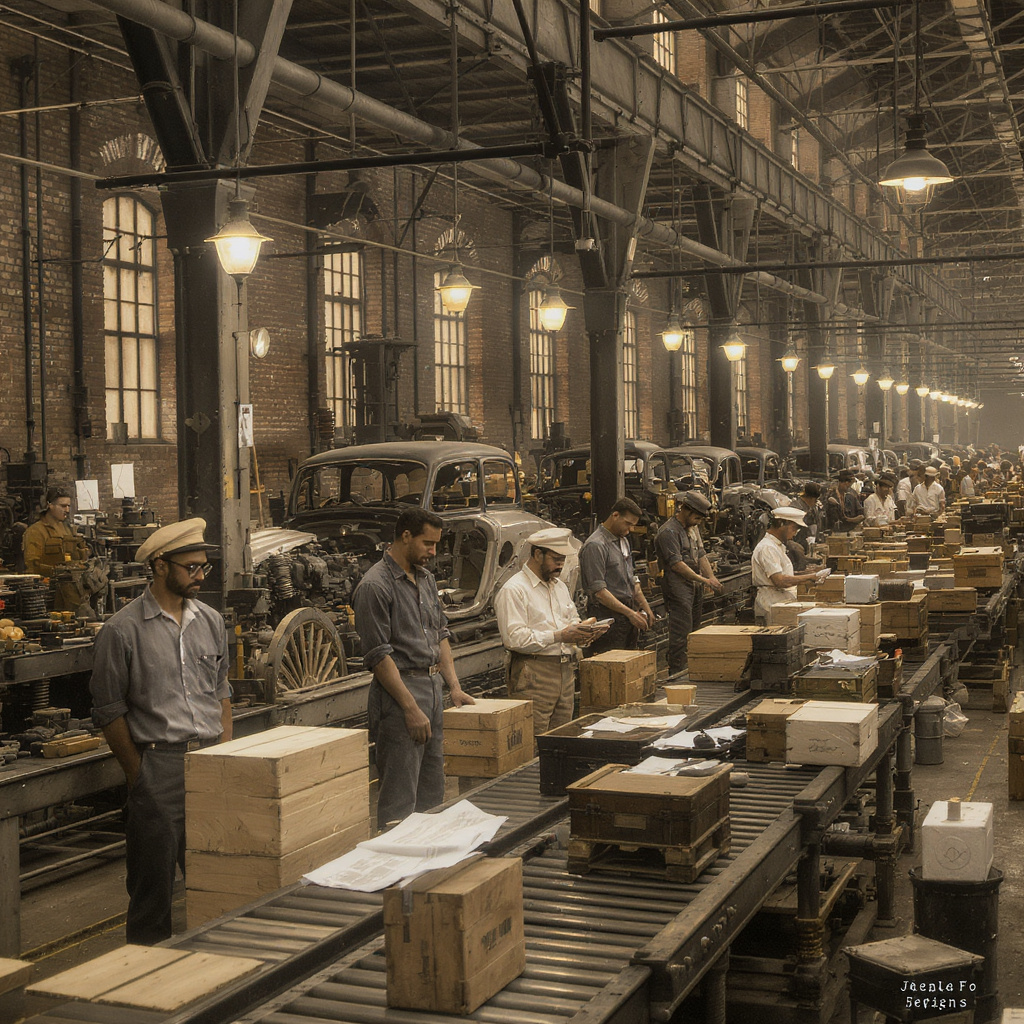

Agile is often packaged as a 21st-century savior for software teams. But if we peel back history, its principles are centuries old. Industrial giants like Henry Ford and shipbuilders of World War II practiced forms of incremental work, cross-functional collaboration, and adaptive delivery. What they lacked in jargon (“scrum,” “kanban”) they made up for in sheer practicality.

- Assembly Lines as Iterations: Ford’s assembly line wasn’t invented in a polished state. Early models were clunky. Workers often paused production to test tweaks. Sometimes a shift in spacing between workstations saved hours; sometimes a redesigned tool reduced errors. Each small adjustment mirrored what we call “iteration” today.

- Risk Reduction by Testing Small: Rather than investing years into a single “big bet” prototype, Ford and his engineers tested parts, tools, and workflows piecemeal. This reduced the cost of failure. Agile carries the same DNA: fail fast, learn, adapt.

- Stakeholder Involvement: Cars weren’t just built for the sake of production. Feedback from dealers, drivers, and even mechanics influenced Ford’s continuous improvement cycle. Agile does the same by pulling end-user feedback into every sprint review.

👉 The industrial past reminds us: Agile isn’t about rituals. It’s about survival through adaptability.

2. Why Iteration Beats Perfection – Then and Now

In traditional craftsmanship, perfection was the goal. A single craftsman would spend weeks or months making a complete product, often discarding failures along the way. Ford flipped this model by prioritizing speed and iteration.

- Industrial Example: Early Model T production wasn’t flawless. The first cars rolled out with problems, but each cycle revealed insights. Instead of stalling until everything was perfect, Ford shipped, learned, and adapted.

- Modern Parallel: In software, a perfect “big bang” release often collapses under real-world use. Agile champions delivering a Minimum Viable Product (MVP) quickly, gathering user reactions, and shaping improvements.

Lesson: Perfection is expensive; iteration is sustainable. A flawed product that evolves is often better than a “perfect” one that never arrives.

3. The Human Side of Agile – Collaboration Over Command

Industrial history also sheds light on a critical Agile value: people over processes.

- Factory Floors as Agile Teams: Workers on assembly lines often identified inefficiencies that managers couldn’t see. A mechanic might spot a recurring defect and suggest a redesign. When listened to, these insights accelerated improvement. When ignored, they slowed progress.

- Unionization as Feedback Loops: Strikes and collective bargaining were, in a way, massive “retrospectives.” Workers demanded changes — shorter hours, safer conditions, fair wages. This feedback, although painful for management, reshaped the system sustainably.

- Agile Translation: Today, daily stand-ups and retrospectives serve the same purpose — ensuring the real doers of the work shape how it evolves. Projects thrive when feedback flows upward, not just downward.

Lesson: A project manager’s job isn’t to dictate; it’s to enable collaboration and create trust. Agile lives or dies by team empowerment.

4. Delivering Value Early – A Century-Old Priority

Agile’s mantra of “working software over comprehensive documentation” has echoes in history. Ford didn’t wait years to produce the perfect car. He delivered something tangible, even if basic, and improved continuously.

- Historical Insight: The Model T wasn’t luxurious or flawless, but it delivered affordable, reliable transport — exactly what the market craved. This quick value delivery secured Ford’s dominance.

- Modern Reflection: Too many projects collapse under scope creep or delayed benefits. Agile emphasizes delivering increments that prove value. Each sprint is a small promise kept.

Lesson: Projects don’t succeed when the Gantt chart is perfect; they succeed when stakeholders see value quickly.

5. The Bigger Picture – Agile as an Attitude, Not Just a Framework

Looking at industrial history, Agile feels less like a methodology and more like a cultural survival mechanism.

- Adaptation to Disruption: Just as factories adapted to machinery breakdowns, supply chain shortages, and changing markets, modern Agile adapts to fast-changing business landscapes.

- Agile Beyond Software: Marketing teams, HR departments, even military operations have adopted Agile principles. The reason is clear: adaptability isn’t optional, it’s universal.

- A PM’s Role Today: We are not “Agile coaches of frameworks” but custodians of adaptability. Our role is to nurture responsiveness in teams, not just tick boxes in ceremonies.

Lesson: Agile is not about sprint velocity charts. It’s about building organizations that can breathe with change instead of suffocating under it.

6. Conclusion – What We Carry Forward

The Industrial Age didn’t invent Agile, but it lived it. Ford’s assembly lines, factory floors, and wartime production lines taught humanity the value of iteration, collaboration, and early delivery. Today, Agile project managers stand on the shoulders of those industrial pioneers.

When you run your next sprint, remember: you’re not just applying a modern framework. You’re carrying forward a 200-year-old lesson — adaptability is the ultimate competitive advantage.

Leave a Reply

You must be logged in to post a comment.